The Fs600 3D printer is a large volume industrial 3D printer, uses Fused Deposition Modeling 3D printing technology to print out variety of large products nicely.Using new completed closed structure, the large volume 3D printer can guarantee the internal temperature of the platform at the time of printing, so as to maintain the optimal temperature of the 3D printing material, reduce the warped of 3D printer filament’s edge and print the works more accurately.The 3D printer is sold by close packing and is not required to be installed by the customer.

The Fs600 3D printer can be mainly used in industrial manufacturing: machine parts, parts, molds, architectural design: models, samples, living supplies: cups, medical domain: skeleton,teeth,household items: small furniture, handicraft items, decoration,crafts: animation models, small crafts, jewelry models or castings.Because of the low price and quality of Fs600 3D printer, the large FDM 3D printer is the best choice for merchants and 3D printing enthusiasts.

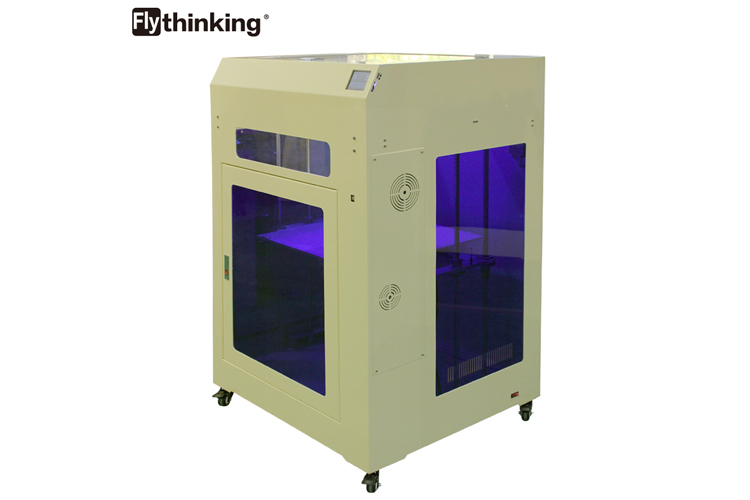

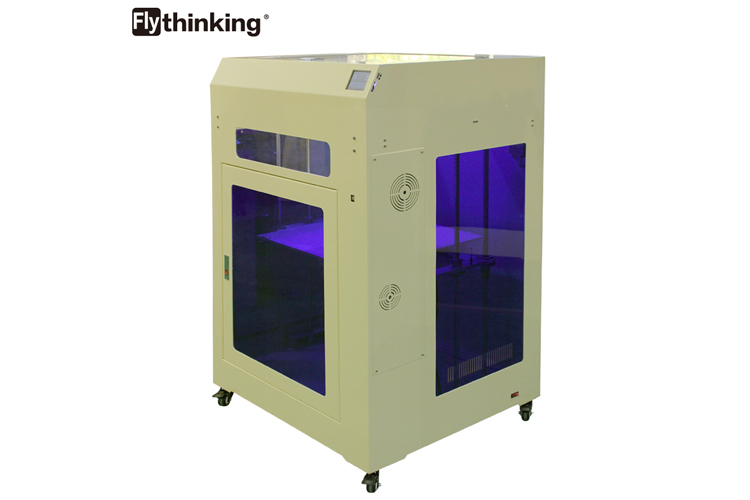

Flythinking FS600 3D printer:

The whole steel structure of the whole machine is stable and stable, and the R&D team is constantly innovating and has carried out many optimization designs, which is more excellent in product performance and easier to operate and use.

1 All metal body, stable structure, effectively reduce the printer body resonance. Compared with the shell of other machines, the mute effect is better. With transparent and organic glass observation window, it is convenient to observe the printing state in real time, which is not only full of dustproof, anti-interference, but also beautiful and generous.

2 Open storehouse design, the refuelling operation is simple, quick.

3 The internal parts of the machine are all made of stainless steel once, with fine structure, and the machining error is less than two filament to ensure the precision of the finished product.

4 The new upgrade motherboard greatly improves the anti-jamming capability, continuously printing 10,000 minutes without failure, and the stability performance is greatly improved.

5 Gantry coaxial driven design, coaxial guide rail drive, drive part resistance pen optical axis transmission greatly reduced obviously, sending machine noise is more obviously, more importantly, gantry machining shaft drive precision is higher.

6 The printing platform is designed with a hot bed, which can avoid printing when the finished product is warped. The maximum temperature can be set to 110 degrees, which is compatible with a variety of printing consumables.