Innovation, integrity, pragmatic and efficient

1,2/F,8/B Yujing industry Dalingshan road Tianhe district,Guangzhou city,China

1.Produce process

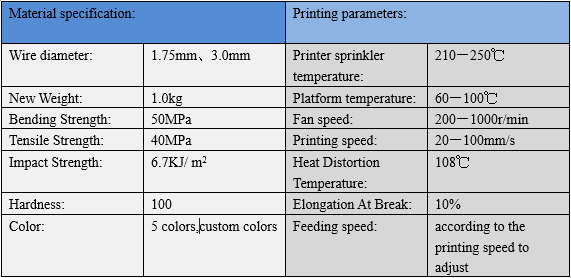

I . Before produce extruding filament ,we will dry the 3D printer filament for a enough time (3-5 hours).

II. Mix with colors masterbatch or colors powder, all which .certified with ROHS.

III.Adjust temperature and dragging rate , make filament diameter range at 1.6-1.8mm/2.8-3.0mm, roundness +/-0.05mm, each spool net weight 1kg+/-0.02kg

IV we put all filament spool in shelf, different kind in different shelf, all categories arranged orderly.

2.Productiong quality control

I. we have diameter laser detect kits to control extruding rate on line, when diameter smaller or higher than accept range, the laser detect kits will adjust the extruding rate higher or smaller to make diameter range at acceptable.

II.keep each record filament samples sent to customers, build a tracking able document.

III.when the filament put on shelf longer than half a year, we will dry the filament again.

3.About waste & recycle

Much time you will find some black filament is too brittle, that added and mixed with some recycle and scrap after produced.

We haven’t produced with scrap outlet, rework&recycle material, or dispose, but for quality assurance purpose.

4.packaging

We put each filament /spool on seal PE bag with desiccant , then smaller carton, then out big box

We also have vacuum heated bag to replace of PE bag, make better avoid moisture.

5.research and developing

we have engineers that specialty in color formulation ,plastic modification, packaging, quality control ,producing control, we can do according to your requirements .

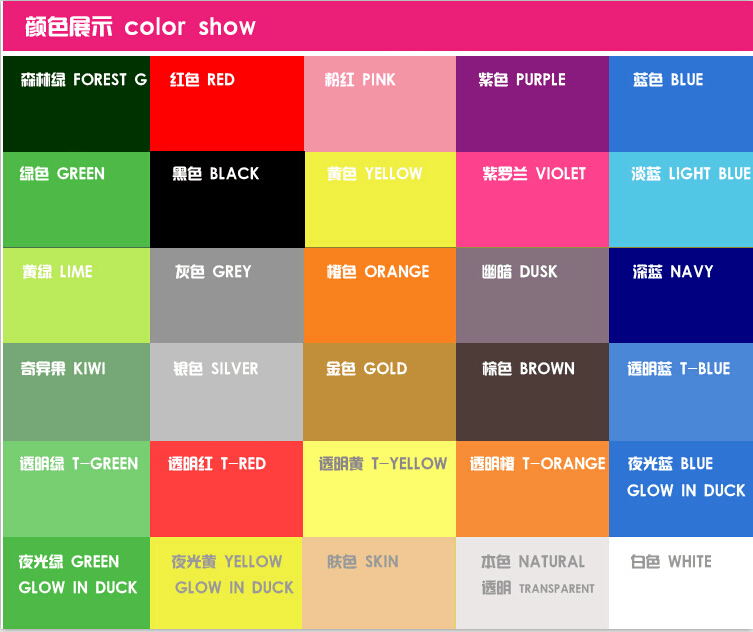

We have colors:

Natural,white,black,red,blue,orange,purple,green,yellow,grey,brown,silever,gold,pink,transparent blue,transparent red,transparent yellow,transparent green,transparent orange,transparent,sky blue, dark blue ,florescent green,violet,skin,lime,dusk,kiwi,glow in dark (green),glow in dark(yellow),glow in dark(blue)etc

Flythinking Technology Co.,Ltd. | Address:1,2/F,8/B Yujing industry Dalingshan road Tianhe district,Guangzhou city,China

TEL:020-82497630 __ 020-82497625

Copyright ? 2023 Flythinking Technology Co.,Ltd. All Rights Reserved.