he space gray 3D printing team used to print a small bridge as a whole. At that time, the purpose of the experiment was to show the difficulties of 3D printing technology in architecture: 3D printed buildings are not afraid to print big, but they are afraid to print small. Soon after, famous universities in the Netherlands, Japan and China also printed Bridges in various ways. However, some printed modules were assembled, some were just part of the bridge, and there was no practical bridge with the same proportion completed by 3D printing in a real sense. Based on this, the space gray 3D printing team was invited to print the practical load-bearing bridge of garden community, and took this opportunity to create the world's first practical arch bridge in China for 3D architectural printing, which is completely completed in the whole sense.

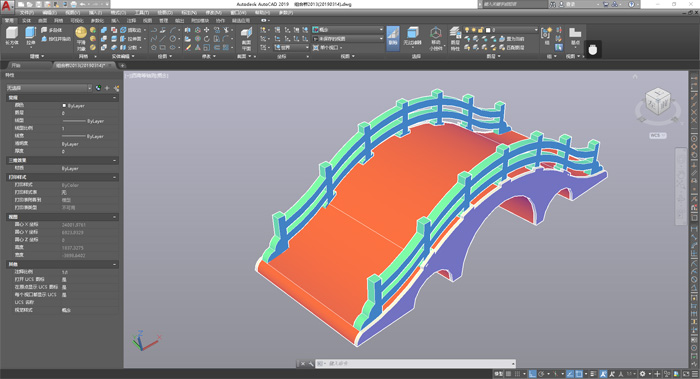

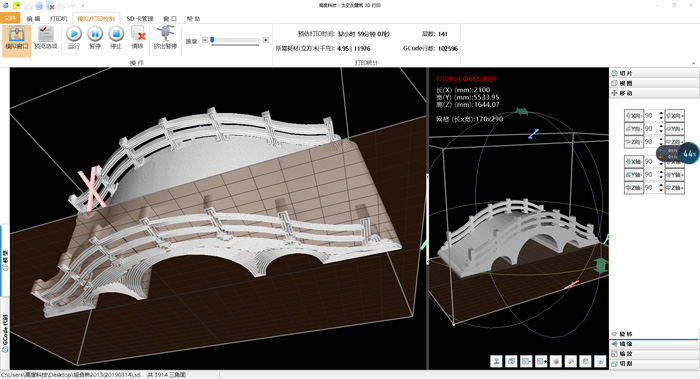

Design architectural model

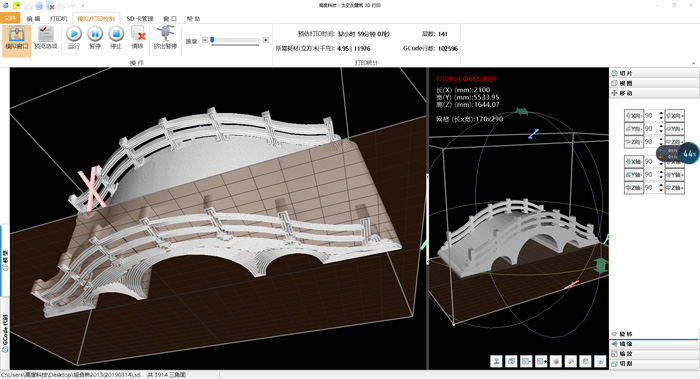

The space gray 3D architectural printing team used AutoCad to design the hole bridge, and imported the model into the 3D printing architectural control system independently developed by space gray to set the printing parameters and slice it.

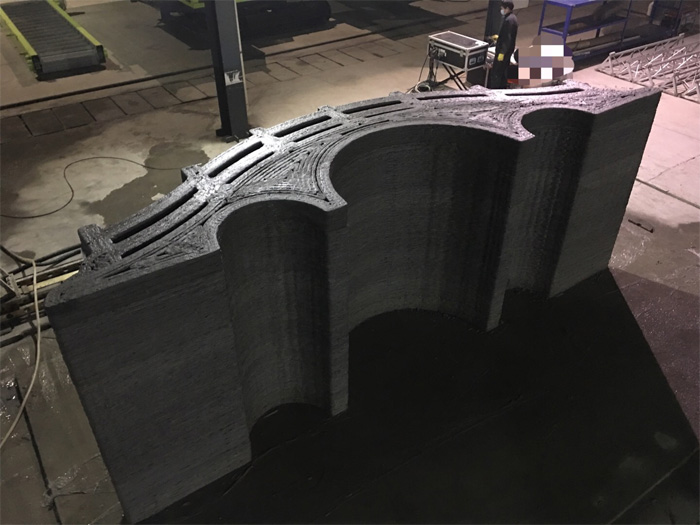

The final printed size of the model is 5.5 meters long, 2.1 meters wide and 1.6 meters high. The printing material is 425 ordinary cement, plus aggregate and steel bar, the total weight is about 10 tons, the printing time is 32 hours and 59 minutes.

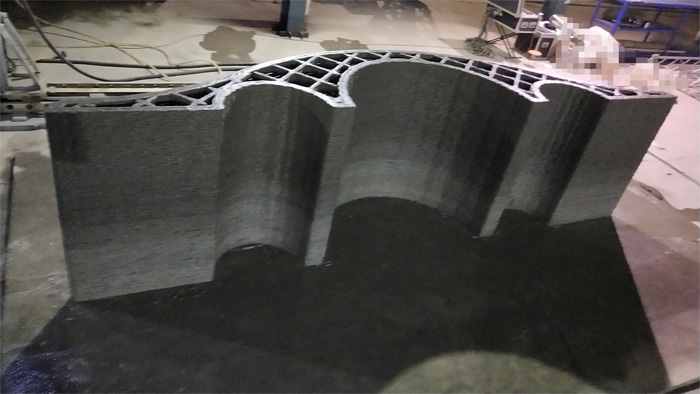

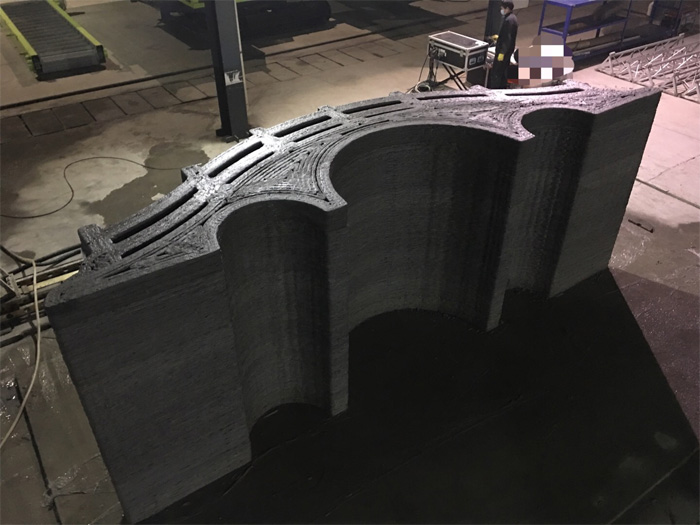

The design of the bridge is a three hole bridge, the normal way to print the process needs to use support materials. Independently developed supporting materials of space gray: hard in texture, light in weight, it can be condensed instantly after printing, easy to remove and recycle; Through the use of double extrusion head printing technology, efficient and rapid one - time molding.

This time, we choose another process to print by standing up the side of the bridge. When the support is needed, another printing process will be adopted. This is also due to the self-developed space gray 3D printing control system and slicing procedures.

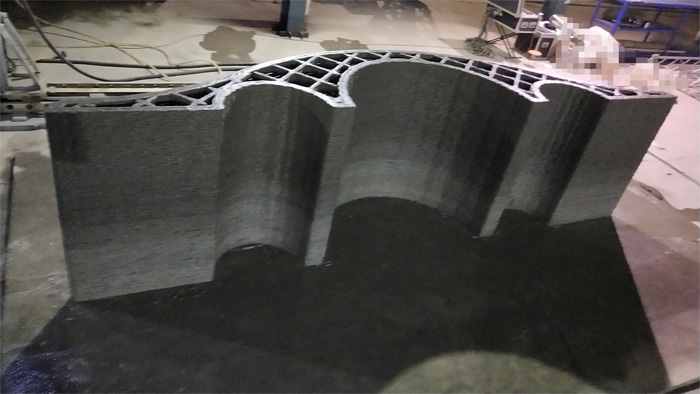

Print bridge body

The main body of the bridge is printed with no technical difficulties for the mature space grey team. From the beginning of the design, the space gray team defined the printed bridge as being capable of passing and passing vehicles, including heavy vehicles, and was designed entirely in accordance with the normal use of the bridge. So when printing, need to arrange a large number of rebar, the control program pause function, break point continue to play, and can adjust the printing speed at any time to make full use of the function.

Another result of this printing is that it can be printed continuously without the limitation of cement setting time and printing height. Due to its inherent characteristics, cement takes a certain amount of time to solidify. This bridge is a little more than 5 meters long. Every time a layer is printed, it only takes a few minutes. If some additives commonly used in the market are added, although it may meet the demand in a short time, it will eventually affect the final setting effect of cement itself. After a long period of experiments, space ash has worked out a way to print continuously. This printing is also verified to meet expectations, that is, the use of ordinary cement can be printed continuously, not limited by the time and height of printing.

Space gray 3D building printing equipment will print in real time according to its special control system and according to the selected slicing scheme. The printing accuracy is measured in millimeters, which is rare in 3D building printing, which is famous for its large equipment. The 3D printing control system is independently developed with abundant functions. It can simulate the printing process and select the most suitable printing scheme before printing according to the requirements and needs.

During the printing process, the printing speed, extrusion amount and printing scheme can be adjusted at any time as required. Pause at any time to meet the needs of cloth reinforcement, etc. When something happens in the middle, the printing can also be stopped and then printed again. The space gray 3D printing system will accurately locate the last printing position, to the point rather than the layer. Each of these seemingly ordinary technologies is a remarkable technological breakthrough in the 3D printing construction industry.

The space gray 3D building printing project has many details in place, such as the placement of steel bars. Some are placed while punching, some are placed after printing, and some are reserved holes or holes in the printing. After printing, steel bars or cage are placed, and then poured. The ultimate purpose is to meet the requirements of building standards. These actions are seemingly simple, but without the cooperation of software system, it is difficult to achieve the above behaviors. Through the printing process, we will understand why space gray 3D building printing has been attracting much attention, especially in the 3D building printing industry.

The overall effect

Printing devices

This printing bridge USES the following construction printer, which has a huge body and a nozzle to extrude cement continuously through the nozzle to construct the building. The size of this printing device is 10 m *5 m *5 m, which is the space gray experiment machine. The space gray team has designed equipment with a maximum size of 50 m *15 m *15 m that can be customized to meet customer needs. Compared with the current experimental prototype, the appearance and function of the real equipment in the market have been greatly changed.

Space gray 3D building printing equipment belongs to the second generation of 3D building printers. Compared with the first generation of 3D building printers, which can only print facade walls, the second generation of printers can print any space surface. With the increasing maturity of the second generation of printing equipment, the space gray 3D architectural printing team will definitely continue to lead the trend of 3D architectural printing in the world and continue to promote the development of 3D architectural printing industry.