Today, 3D printing is no longer a novelty. The idea for this technology originated in the United States at the end of the 19th century; It was developed and popularized in the 1980s; In the new century, with the development of basic scientific research such as computer technology, material science and imaging technology, 3D printing has been widely applied. No wonder it is called "the idea of the last century, the technology of the last century and the market of this century".

The aerospace and medical industries were the first to use 3D printing, and now 3D printing has achieved considerable application in both fields. Among them, the medical device industry is one of the most important markets for 3D printing. It can realize personalized and accurate medical services, and the demand is growing rapidly. For example, medical models, surgical guides, dental and orthopedic implants, tissue and organ bio-printing, etc. are gradually entering into clinical practice, and some of them have achieved large-scale production.

Since 2000, according to Wholers Associates, a us consultancy, more than 60m hearing aid cases and ear moulds have been customised using 3D printers. Hundreds of thousands of patients have been fitted with 3d-printed orthopedic implants, ranging from artificial hips to titanium jaws and prosthetics. 3d-printed surgical guides make surgery more accurate and benefit countless patients. About 100,000 knee replacements are performed in this way each year. Hospitals and surgeons such as oral and maxillofacial surgeons are also increasingly 3D printing medical models. Using anatomical data from tools such as magnetic resonance imaging (MRI) and computed tomography (CT), 3D printed medical models can not only preserve a high level of detail, but also save a lot of time and money.

It is not surprising that the medical industry has embraced additive manufacturing so quickly. People come in all sizes, so the ability of 3D printers to be customised is a boon. Computer-aided design (CAD) software controls these printers, directing them to build objects by piling up layers of material, and the medical scans are actually CAD files. Tools in traditional factories are better suited to mass producing identical products, while software changes are faster and cheaper.

▲ 3d-printed aortic valve

1. Organic silicon successfully realizes 3D printing

The maturity and expansion of materials has always been one of the important factors in the development of 3D printing technology. In the medical field, because it is a very special application field, higher requirements are put forward for physical and chemical characteristics, process flow and software of 3D printing materials, especially for the biological compatibility of materials and products. Currently, materials that can be used for 3D printing include resins, alloys (such as nickel-based chromium, cobalt, aluminum, titanium, etc.), polymers, ceramics, plastics, etc. Among them, as a mature and widely used polymer elastomer in the medical industry, the biggest advantage of organic silicon is simple composition, safe and reliable, with good biocompatibility. Silicone elastomer has excellent flexibility and elasticity, and its appearance and touch feel are closer to human body than other materials.

Previously, organosilicon molding was based on a complex injection molding process: the manufacturer must first prepare the mold and then pressurize the liquid silicone rubber into it. This method is too expensive and only suitable for mass production. Organic silicon 3D printing enables completely new component design.

Organic silicon 3D printing can cover different life cycles of products. Without using any tools or molds, digital models can be directly converted into physical objects, thus reducing production costs, saving production time, greatly shortening process cycle, and rapidly improving products during product development. On the other hand, organic silicon 3D printing can also integrate functions of complex functional parts and prototypes.

However, silicone, a special soft adhesive material, is extremely difficult to achieve 3D printing. As a supplier of organic silicon materials with a history of more than 70 years, wacker chemical is one of the earliest companies in the world to develop organic silicon 3D printing technology. ACEO® 3D printing technology is the world's first industrial-grade technology for additive manufacturing of liquid silicone rubber components. Its unique "inkjet on demand" technology enables ACEO® to achieve full design freedom for printing highly functional components, while maintaining high temperature resistance, radiation resistance and biocompatibility of silicone rubber. The application of ACEO® 3D printing technology in the medical field will obviously bring great benefits to the development of the entire industry and the well-being of patients.

▲3D printed blood vessels

2. Medical model

Medical models have significant advantages in today's medical applications. They are useful in clinical training, surgical planning visibility and simulation, disease notification, and simulation in the development of medical devices, and can even be used as customized models for precision prosthetics. Medical models are playing an increasingly important role in clinical applications, universities and research institutions because they look and feel more like human bodies than other materials.

3D printed medical models can be used to create organic structures with complex internal structures and have a wide range of applications. Organic silicon is flexible, deformable and easy to cut and sew. With such models, doctors can show patients what is going on inside their organs and what treatments are needed. For example, surgeons can use imaging data to 3d-print a patient's heart and preview procedures in near-real conditions to predict and reduce unexpected problems during surgery.

ACEO® 's unique "on-demand inkjet" technology, based on organosilicone elastomers, is used to print complex three-dimensional anatomical models. The fidelity of such models to simulate biomechanics has reached an unprecedented level. Silicone elastomer has excellent flexibility and elasticity, and is easy to cut and suture, especially suitable for replicating soft tissues such as blood vessels, heart, muscle or skin.

ACEO® 3D printing technology is being used to replicate human organs to create biocompatible silicone rubber components, which are in growing demand in the scientific and medical industries. All ACEO® generic materials have been certified for biocompatibility by ISO10993 and USP Class VI.

ACEO® global marketing director Egbert Klaassen says, "the anatomical models printed with real silicone elastomers demonstrate the extreme fidelity that can be achieved by anatomical models. Working with experts from universities, clinics and research institutions, wack has developed a basic product line that includes models of blood vessels, aortic arches, aortic valves and tricuspid valves, and plans to roll them out to the mass market. Customers can order the models directly or upload the models they need through the ACEO® online store." ACEO® 3D printing service has been launched on the Chinese website and online store.

3. Artificial gums

Dentistry is by far the most mature medical field for 3D printing. According to the research of SmarTech Markets, the 3D printing market in dentistry and medicine is expected to reach $4.544 billion by 2020. The digitisation of dentistry goes back 20 years. The standard manufacturing procedure for crowns at that time was to obtain dental impressions and then send them to the laboratory to be cast with plaster. The dental technician then 3D scanned the plaster to create the CAD structure. The data is then sent to a CNC milling machine or a metal 3D printer to produce custom crowns. What has changed in this period is that dentists rarely used 3D scanners in the mouth until this century. Over time, dental impressions and plaster parts have been phased out.

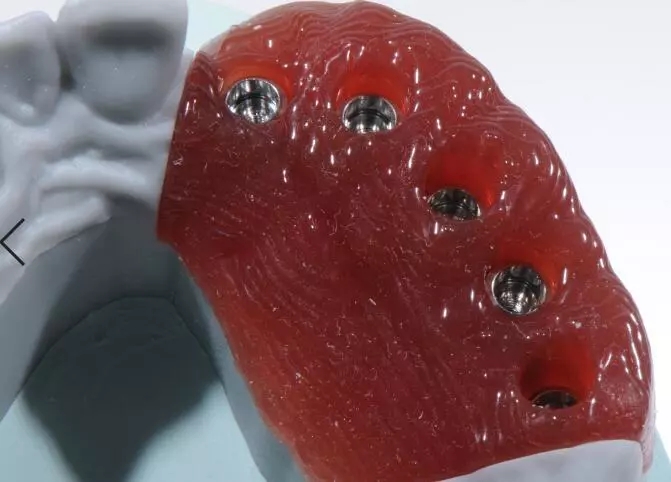

ACEO® was recently selected by the dental laboratory of the general hospital for oral prosthodontics in Munich for a project to further promote the use of additive manufactured artificial gums. Artificial gums are used to simulate the real gingival conditions of patients in the field of oral implantation. When used together with the printed tooth model, the pathological conditions of patients can be clearly reflected. Digital and physical imprints of the patient's mouth are available, but the softness and sensitivity of real gums cannot be digitally calculated. Therefore, creating the perfect crown requires a more realistic gingival model, made of a softer material than plaster and capable of changing shape.

▲ artificial silicone rubber gums were printed using ACEO® 3D printing

Silicone has properties similar to gums. They are impermeable and have passed tests on class IIa medical devices. They come in different hardness and colors, so the 3D printed parts look and feel realistic. On the other hand, no reduction technology suitable for organic silicon processing has been developed at present. When data is obtained by 3D in-mouth scanner, the only way to create solid models is milling or printing. ACEO® is a high-quality material that is cured with ultraviolet light and without plasticizer, so it does not affect tactile or mechanical properties. It provides the perfect solution for making artificial gums.

4. Prospects and challenges

Organic silicon 3D printing is an emerging technology, but it has been applied gradually. In the future, it will be more and more widely used in industrial fields. Taking advantage of 3D printing's insensitive to complex shapes and no need to open molds, more and more innovative designs are emerging and production efficiency is effectively improved. The world is not only exploring the potential of 3D printing for prototype printing, small batch printing, and component printing, but also increasingly using the advantages of true 3D structures for innovative designs, such as anatomical models, the use of lattice structures, and robotic grippers. Silicone 3D printing based on MRI or CT data shows the endless possibilities. In the future, many new applications will emerge. Custom-made silicone breathing masks and hearing AIDS, for example, will soon be available through 3D printing.

However, the development of a new technology has always been accompanied by obstacles. Due to the lack of awareness of 3D printing and unclear qualification process standards, some low-performance products have appeared on the market, damaging the reputation of silicone. This is especially true for users who do not know silicone from traditional processes. Therefore, professional organizations, industry associations and other institutions should actively solve the problem of standard formulation of organic silicon 3D printing. Manufacturers should work closely with customers to make production more flexible and respond quickly to different needs using organic silicon 3D printing technology.

I believe that in the near future, with the maturity and improvement of many 3D printing materials including organic silicon, skillful women will no longer be able to cook without rice. Advances in materials science, 3D printing and other technologies will continue to drive revolutionary changes in the medical industry.